The Kit comes with lots of premium parts. The chassis comes partially built with the transmission and other plastic parts already installed. You get a sweet Flo-Tek and some pre-mounted tires.

Check out the chassis here. The weight distribution feels good, but as more parts are added, the center of gravity quickly shifts to the rear.

I added the carbon braces right off the bat in order to stiffen up the shock towers. The plastic is very flexible with this truck, and it can be bent to extreme angles without breaking. This truck is beefy and it designed to not break.

It took me a good 8 hours to get the kit put together the way I liked. I ended up replacing the shocks that come with the kit with the Pro-Spec shocks from Proline. I will cover the build of those in another post.

After I got the truck together, I took it for a little drive in the street and I noticed that the truck would not stop doing wheelies. The placement of the battery needed to be put all the way forward, but my electronics did not have long enough wires. I ended up buying some 6 inch extension wires so that I could move the battery all the way forward and move my electronics wherever I wanted.

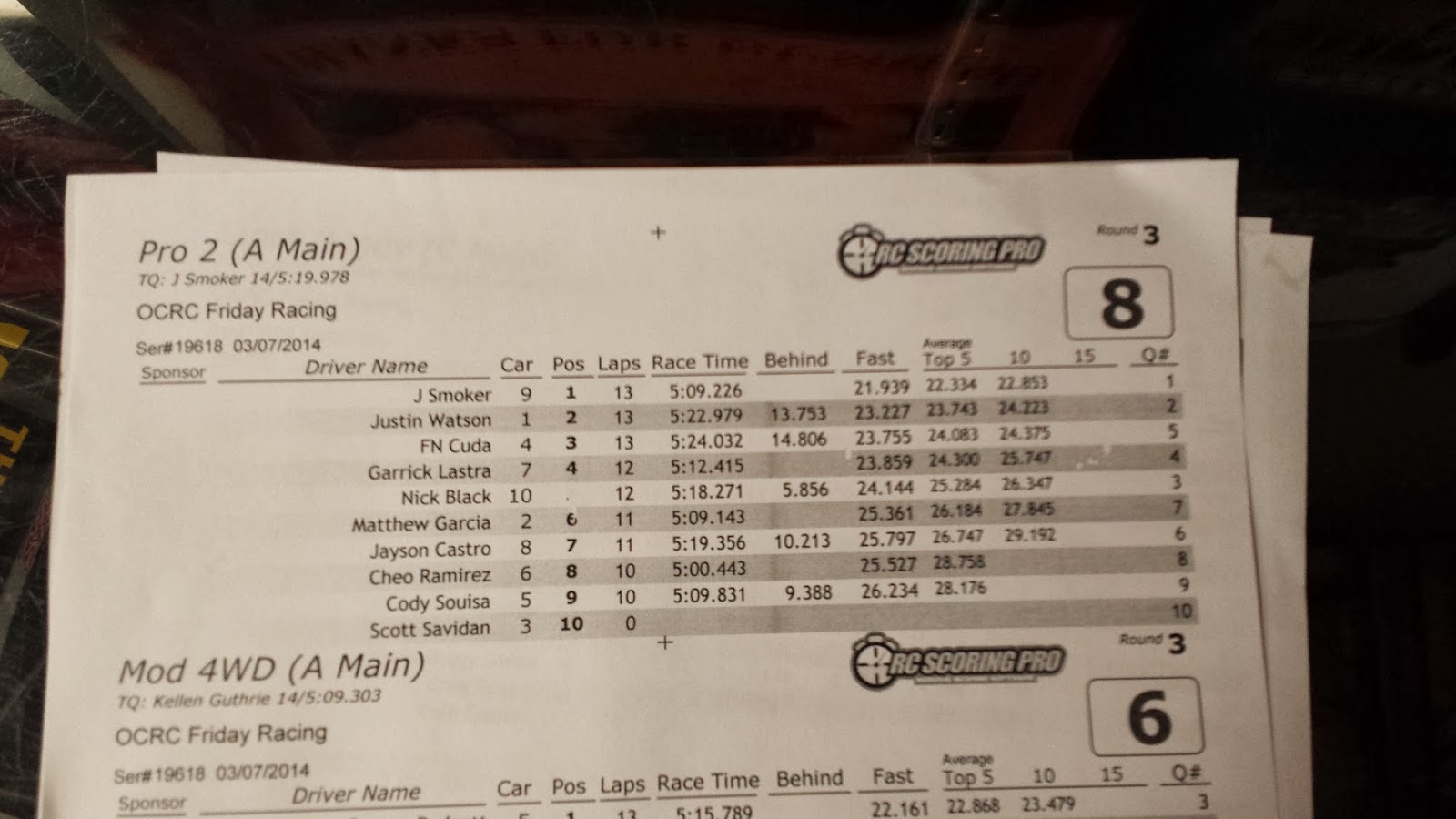

After adjusting the battery position, the truck handled amazing. I did notice that the steering was a little sluggish, but that was fixed by replacing the servo saving linkage with a fixed one. While at the track the other week, I noticed another driver break his Proline Pro-2 in a race, but the truck was not actually broken. The front C hubs are very flexible plastic and they merely warped out of position. I decided to upgrade the hubs with some aluminum parts from STRC. I will show the steering and hub upgrade in another post. Overall my first impressions of the truck are good. We will see how it works this friday at the races.

Good luck at the races! Remember, you can always ask me for help, just look for the Pro-Line vehicles with the KLA logo at the track.

-Matthew Garcia